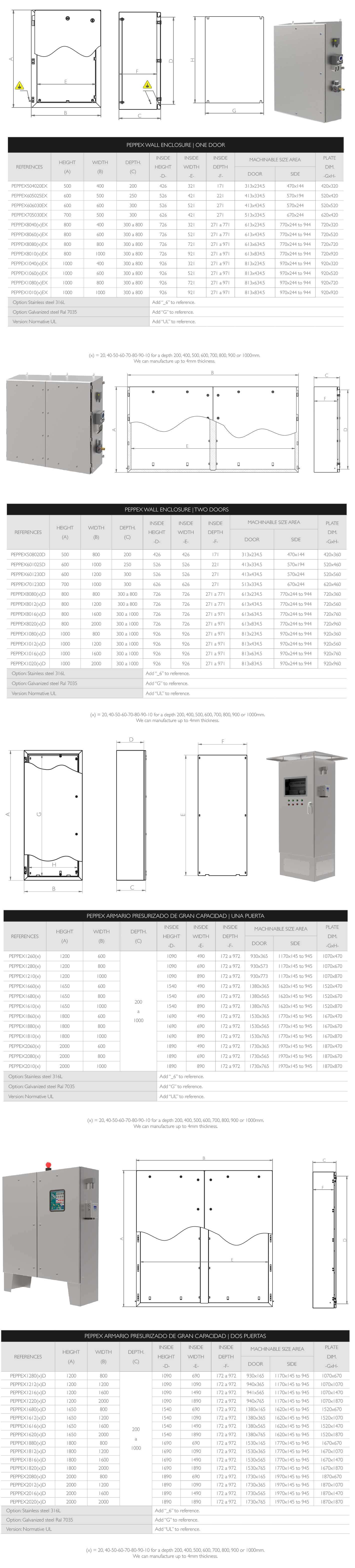

Pressurized Panel enclosure Ex p, Px, Py, Pz Peppex series allow non Ex elements to be fixed inside, All our manufacturer pressurized Ex enclosures and Cabinets are anti-corrosion made in 304L or 316L stainless Steel. They have been strictly checked to guarantee an Ex P safety degree which includes the rest of degrees:

Pressurized panel cabinets & Enclosures Ex px, Ex py y Ex pz.

We also manufacture customized pressurized panels certified USA normative by UL Nema 4x and nfpa 496.

In Atex Delvalle we are very aware of the importance of safety in high-risk areas. For this reason our team of engineers, using the existing knowledge about special cabinets for gas, petrochemical and pharmaceutical industries, has specifically developed a range of solutions with pressurized, anti-corrosion certified enclosures. These are all certified according to ATEX 94/9/EC European standard and American UL. Pressurized Enclosure ex

Px - Zone 1 pressurized panels

This is the most common type of pressurised panel we produce giving a protection level of EPL Gb or Atex category 2. This will allow us to use standard industrial parts inside the control panel. Depending on the load inside the Ex p panel they are often supplied with an additional Ex de panel containing a breaker of some sort to isolate the power source if overpressure is lost.

The panels themselves are for the most parts custom made to order allowing us to custom make shape and size. The material we use is for the most part 316 SS but other materials may be used.

These panels are individually certified as one of the tests involves an evacuation test using Helium (representing a light gas) and Argon (representing a heavy gas) to allow us to set the purge period required. We try to produce the panels with a low leakage rate that will allow our clients to run the system under very low pressure, thus putting less stress on the panels, but we also test the panels to maximum leakage rate to allow the client to adjust for aging.

Py - Zone 1 pressurized panels

This protection method is identical to type Px but the internal parts are certified for zone 2 locations. This enables the end used to use a less stricken shut down philosophy should he desire to do so. From a certification point of view you do not have to shut down in the event of loss of overpressure, an alarm at a manned location will give you a grace period before you have to shut down.

This type of protection may also be used if you want to have a higher degree of safety on the equipment as the internals are zone 2 rated. A lot of zone 2 rated control equipment does exist today, and several more are being introduced into the marked, allowing larger systems to be manufactured.

Pz - Zone 2 pressurized panels

This protection method is identical to type Px, with a lower degree of safety. These control panels will provide a protection level of EPL Gc or Atex category 3.

The panels are for the most parts more or less identical to that of an Px panel, but the control circuit is simplified. Some clients also use this technique as environmental protection for control panels.

pressurized panels with Pressurization Ex p, (x) (y) (z) is a protection system specially designed for hazardous or aggressive environments which get classified as Zones 1,2, 21 and 22.

Atex Delvalle recommends pressurization panels which cannot be protected by any other means, either for being too large (which prevents them to become flameproof).

Or because they require too high power to benefit from the enclosure’s intrinsic safety, and hazardoust zones.

This technique is more and more used to protect electric pressurized enclosures as it provides additional safety.

In Atex Delvalle we are very aware of the importance of safety in high-risk areas.

For this reason our team of engineers, using the existing knowledge about special cabinets for gas, petrochemical and pharmaceutical industries, has specifically developed a range of solutions with pressurized, anti-corrosion certified enclosures.

These are all certified according to ATEX 94/9/EC European standard and American by UL.

Px - Zone 1 pressurized panels

This is the most common type of pressurised panel we produce giving a protection level of EPL Gb or Atex category 2. This will allow us to use standard industrial parts inside the control panel. Depending on the load inside the Ex p panel they are often supplied with an additional Ex de panel containing a breaker of some sort to isolate the power source if overpressure is lost.

The panels themselves are for the most parts custom made to order allowing us to custom make shape and size. The material we use is for the most part 316 SS but other materials may be used.

These panels are individually certified as one of the tests involves an evacuation test using Helium (representing a light gas) and Argon (representing a heavy gas) to allow us to set the purge period required. We try to produce the panels with a low leakage rate that will allow our clients to run the system under very low pressure, thus putting less stress on the panels, but we also test the panels to maximum leakage rate to allow the client to adjust for aging.

Py - Zone 1 pressurized panels

This protection method is identical to type Px but the internal parts are certified for zone 2 locations. This enables the end used to use a less stricken shut down philosophy should he desire to do so. From a certification point of view you do not have to shut down in the event of loss of overpressure, an alarm at a manned location will give you a grace period before you have to shut down.

This type of protection may also be used if you want to have a higher degree of safety on the equipment as the internals are zone 2 rated. A lot of zone 2 rated control equipment does exist today, and several more are being introduced into the marked, allowing larger systems to be manufactured.

Pz - Zone 2 pressurized panels

This protection method is identical to type Px, with a lower degree of safety. These control panels will provide a protection level of EPL Gc or Atex category 3.

The panels are for the most parts more or less identical to that of an Px panel, but the control circuit is simplified. Some clients also use this technique as environmental protection for control panels.

All products manufactured by Atex Delvalle comply with ATEX and IECEx certification to answer the strictest requirements worldwide. We also comply with the UL Standards as well as CE certifications.

In general, all risk areas where a flameproof product is necesary. Specially designed for: